Toll Gas Gives you a Competitive Advantage by Making Robotic Welding Affordable

App Based Cobot Teaching

Use the intuitive Hirebotics iPhone or Android App to easily teach and program the cobot your specific welding requirements. Whether you’re buying your first robot or adding to your existing line, Hirebotics robot systems can be setup in just one hour.

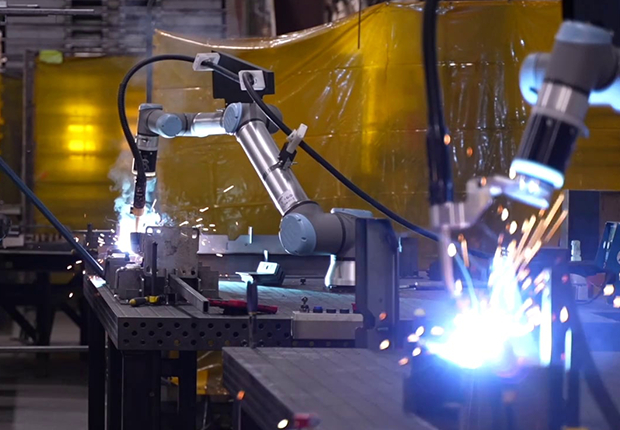

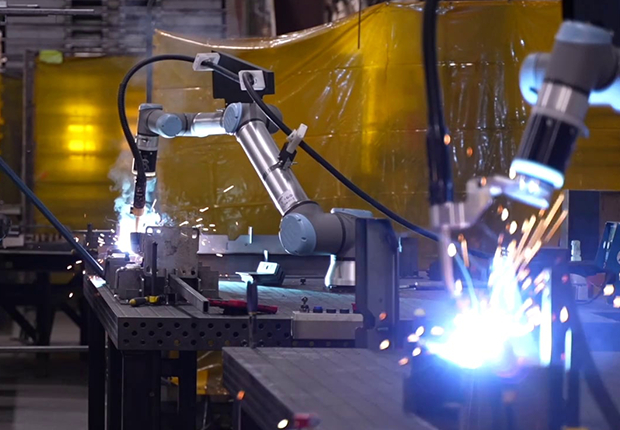

High Quality Robotic Welding

The efficiency of welding cobots allows your company to be able to accept more jobs or speed up your time-to-market. The faster time-to-teach makes small batch manufacturing affordable and efficient.

What is Included in the Cobot Welder Package?

- Universal Robots UR10e Collaborative Robot(51″ reach)

- Miller Cobot Welding Package, including an Invision

352 MPa pulsed welder and S74 feeder - Tregaskiss Tough Gun MIG welding gun

- Hirebotics’ Smart Puck for software-free teaching

- Siegmund 48″ x 32″ welding cart (size options)

- Operator panel with emergency stop for quick program start

Robotic Welding Frequently Asked Questions

While cobots have numerous safety features built-in and do not require safety cages like traditional automation, there are some important safety items to keep in mind when cobot welding.

Most importantly and just like manual welding, your welders need proper PPE. You’ll also want to make sure you protect your welders with arc flash protection like you do for your manual weld stations. And don’t forget fume extraction.

Generally, our lead time is approximately 2 weeks from receiving your PO. Reach out to us at any time about our current lead time if you need a system sooner!

The maximum speed of the cobot is approximately 1 meter per second. However, the Cobot Welder utilizes the built-in safety controller of the Universal Robots UR10e to limit the maximum speed during welding to approximately 110 inches per minute. If you need to weld faster, reach out so we can understand your needs a bit more.

The cobot used in the Cobot Welder is the Universal Robots UR10e. It has a maximum reach of approximately 51″. Each joint has full 360º rotation.

It depends on numerous factors including the type of material, type of welding, part size, and more. The best way to know for sure is to reach out to us for a demo so we can best assess your application needs.